When we talk about breakthroughs in advanced manufacturing, ceramic injection molding (CIM) is one of the most exciting technologies pushing boundaries. This process, as practiced at Wunder-Mold, combines the versatility of injection molding with the remarkable properties of ceramics, opening new doors for industries where precision, durability, and safety are everything. Both the aerospace and medical sectors are at the forefront of adopting CIM, and the results are impressive.

Ceramic Injection Molding: From Ancient Material to Modern Marvel

Before diving into specific applications, it’s worth understanding why CIM is considered revolutionary.

Ceramic injection molding blends fine ceramic powders with a binding material to form a moldable mixture. Once injected into custom molds, the binders are carefully removed, and the part is sintered at high temperatures, resulting in an incredibly dense and strong product. What makes this so powerful is the combination of high hardness, corrosion resistance, and dimensional precision that few other materials can achieve.

Aerospace Takes Flight with CIM

The aerospace industry thrives on innovation, and CIM is helping it soar higher.

High-Temperature Strength

Aircraft engines, space shuttles, and hypersonic vehicles operate in extreme thermal environments. Ceramics created through CIM can endure blistering temperatures without losing strength or stability, making them perfect for turbine components and heat shields.

Precision Manufacturing at Scale

Aerospace engineers require parts that are consistent down to microns. CIM enables near-net-shape production, which reduces machining time, waste, and errors. This precision translates to cost savings and higher reliability in mission-critical parts.

Lightweight Efficiency

Weight reduction is a constant priority in aerospace design. Ceramics, when engineered correctly, offer high strength at a lower weight compared to metals. That means better fuel efficiency, longer range, and more room for payloads.

Ceramic Injection Molding: The Medical Industry Embraces CIM

Just like aerospace, the medical field demands absolute reliability. Ceramic injection molding (CIM) is meeting that demand with remarkable versatility.

Biocompatible Implants

Materials like zirconia are ideal for dental crowns, hip replacements, and joint components. Their biocompatibility and wear resistance mean fewer complications and longer lifespans for implants, improving patient outcomes.

Surgical Tools Built to Last

Surgical instruments made from ceramics resist corrosion and withstand repeated sterilization cycles. They hold sharp edges longer and reduce wear, offering better performance in operating rooms.

Miniaturization of Devices

Modern medicine often requires extremely small, complex components. From microfluidic chips to connectors in diagnostic devices, CIM can produce intricate geometries that would be impossible or prohibitively expensive with traditional machining.

Shared Advantages of Ceramic Injection Molding Across Industries

Both aerospace and medical applications benefit from the same core strengths of ceramic injection molding.

- Exceptional hardness and wear resistance ensure long-lasting parts.

- Scalability makes CIM cost-effective once molds are developed.

- Customization allows manufacturers to tailor parts for unique needs.

These qualities make CIM a standout solution wherever precision and performance are non-negotiable.

Overcoming the Challenges

Like any technology, CIM has its hurdles.

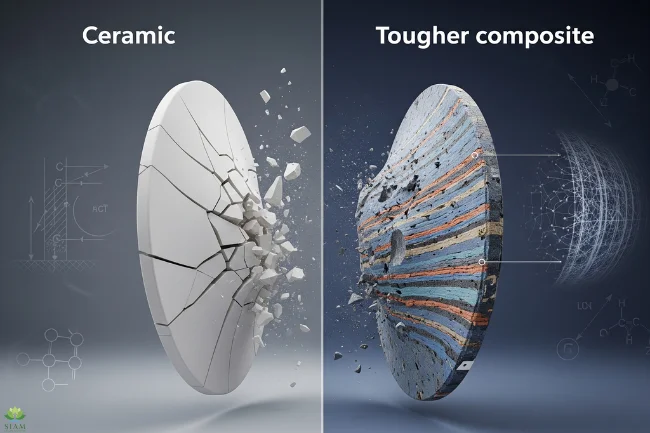

- Ceramics can be brittle, but tougher composites are being developed.

- Tooling costs are high, though they pay off in mass production.

- Post-processing steps like sintering require precision, but advancements in technology are reducing risks and defects.

The industry’s ability to innovate is steadily addressing these challenges, paving the way for even wider adoption.

Looking Toward the Future of Ceramic Injection Molding

The potential of CIM is only beginning to unfold. Aerospace engineers are experimenting with ceramic composites that combine strength with electrical or thermal conductivity. Medical researchers are exploring smart implants that integrate sensors within ceramic structures.

Fun fact: The earliest commercial uses of ceramic injection molding were for spark plugs in the early 20th century, and today, it is helping power rockets and heal people through advanced implants.

Ceramic injection molding is not just another manufacturing method – it is a transformative process redefining what’s possible in aerospace and medicine. Merging precision with the inherent strengths of ceramics allows engineers and doctors to achieve things once thought impossible. As technology continues to advance, CIM is set to play an even greater role in shaping safer skies and healthier lives.

Salman Khayam is a business consultant at Siam IT Solutions, specializing in digital marketing, PPC, SEO, web development, e-commerce, and email marketing. He designs custom strategies that deliver measurable success.